CHEMOCET Master Organic Colour (MOC) and its related range of products are organic pigment mono Concentrates for plastics and PP fibre.

CHEMOCET Pigment Preparations are aimed at meeting the requirements of plastic compounders, especially master batch producers as they offer many technical and economic advantages.

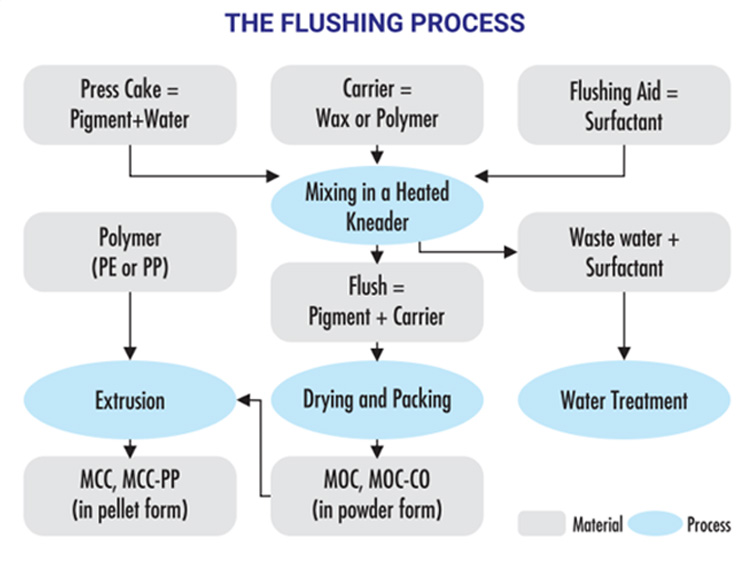

The CHEMOCET MOC range of pigment preparations for plastics are produced by a unique process called flushing. This process starts with pigments in a press cake form as opposed to the normal dispersion process that uses pigments in dry form.

When synthesized pigments are in the form of very small crystals called primary particles. The aim of pigment synthesis is to produce primary particles of sizes that optimize the pigment application properties such as color, strength, tone, brightness, transparency, opacity and rheology. The press cake contains the pigment in this optimum, disaggregated form.

During the drying of the pigment press cake, primary particles join together to form aggregates and agglomerates. Despite milling of the dry pigment by producers, these aggregates and agglomerates are not completely broken down.

It remains the job of the pigment user to further breakdown the aggregates is a dispersion process to achieve the optimum properties of the pigment. This dispersion process requires intimate wetting of the pigment by the polymer to achieve optimum dispersion. This is often difficult with polymers which have poor wetting characteristics and high viscosities.

The flushing process by-passes this pigments with optimum particle size is dispersion step. A press cake containing mixed with the carrier, such as a wax. Under the right processing conditions, and in the presence of suitable additives, the pigment transfers from the aqueous phase (press cake) to the organic phase (wax) while retaining the original size. The result is a dispersion of the pigment in the wax that retains the original particle size of the pigment at high concentrations

| Product Name | CI. Name | Range Availability | Properties | Food Contact Compliance | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MOC | MOC/CO | MCC | MCCPP | Heat Stability | Light Fastness | Migration Resistance | USFDA 21 CFR | AP(89)1 | ||

| Lemon Yellow | Yellow 13 | √ | √ | √ | × | 200 | 6-7 | 3 | × | √ |

| Sunshine Yellow | Yellow 17 | √ | √ | √ | × | 200 | 6-7 | 3 | × | √ |

| Bright Yellow | Yellow 62 | √ | √ | √ | √ | 250 | 7 | 5 | × | √ |

| Golden Yellow | Yellow 83 | √ | √ | √ | × | 200 | 6-7 | 4 | × | √ |

| Canary Yellow | Yellow 168 | √ | √ | √ | √ | 250 | 7 | 5 | × | √ |

| Brilliant Yellow | Yellow 191 | √ | × | √ | × | 300 | 7 | 5 | √ | √ |

| Brilliant Orange | Orange 13 | √ | √ | √ | × | 200 | 5 | 3 | √ | √ |

| Deep Orange | Orange 34 | √ | √ | √ | × | 200 | 7 | 3-4 | √ | × |

| Deep Green | Green 7 | √ | √ | √ | √ | 300 | 8 | 5 | √ | √ |

| Deep Blue HT-1 | Blue 15:1 | √ | √ | √ | √ | 280 | 8 | 3-4 | √ | √ |

| Brilliant Blue | Blue 15:3 | √ | √ | √ | √ | 300 | 8 | 5 | √ | √ |

| Deep Blue | Blue 15:0 | √ | √ | √ | × | 200 | 8 | 3-4 | × | √ |

| Brilliant Magenta | Violet 19 | √ | × | √ | √ | 300 | 8 | 5 | √ | √ |

| Brilliant Violet | Violet 23 | √ | × | √ | √ | 260 | 7-8 | 4-5 | × | √ |

| Brilliant Pink | Red 122 | √ | × | √ | √ | 300 | 8 | 5 | × | √ |

| Blood Red | Red 170 | √ | × | √ | √ | 250 | 7-8 | 2-3 | × | √ |

| Brilliant Red | Red 48.1 | √ | √ | √ | √ | 240 | 6 | 4-5 | × | × |

| Scarlet Red 28 | Red 48.2 | √ | √ | √ | √ | 240 | 6 | 4-5 | × | √ |

| Fire Red | Red 48.3 | √ | √ | √ | √ | 240 | 6-7 | 4-5 | × | √ |

| Tomato Red | Red 53:1 | √ | × | √ | √ | 260 | 4-5 | 4-5 | × | × |

| Deep Red | Red 57:1 | √ | √ | √ | × | 240 | 6 | 4-5 | × | √ |

I – Heat stability is determined in PE by injection moulding method in mass tone.

II – Light fastness and migration resistance are on a scale of 1-8 and 1-5 respectively in PE in mass tone.

III – The pigment is listed in USFDA 21 CFR 178.3297.

IV – The Pigment meets the purity criteria defined in EU AP (89) 1.

V – For food contact application, migration levels are important and must be determined for each specific application.

309, 310 – Blumen,

Station Road, Vikhroli (W),

Mumbai-400083, India.

All Rights Reserved By CHEMOLIN